The Importance of Oil Engine Coolers in Diesel Engines

In the world of diesel engines, optimal performance and longevity are paramount. One critical component that plays a vital role in achieving these objectives is the oil engine cooler. This essential part of the engine’s cooling system ensures that the oil remains at an optimal temperature, preventing overheating and maintaining the overall health of the engine. In this article, we will delve into the functionality, benefits, and maintenance of oil engine coolers, shedding light on their significance in the realm of diesel engine parts.

Understanding the Oil Engine Cooler

An oil engine cooler is designed to regulate the temperature of the engine oil as it circulates through the diesel engine. By doing so, it keeps the oil within an ideal operating temperature range, which is crucial for providing adequate lubrication to engine components, reducing friction, and preventing wear and tear.

Modern diesel engines operate under high pressures and temperatures, making effective lubrication vital. That's where the oil cooler comes into play. It cools the engine oil that is heated during the combustion process, thus maintaining the oil's viscosity and ensuring that it performs its job effectively.

How Does an Oil Engine Cooler Work?

The operation of an oil engine cooler can be summarized in a few steps:

- Oil Circulation: When the engine runs, the oil pump circulates oil from the sump to various engine components for lubrication.

- Heat Absorption: As oil lubricates the engine parts, it absorbs heat generated from friction and combustion.

- Cooling Process: The hot oil then flows through the oil cooler, where it is cooled down either by air or engine coolant, depending on the design.

- Return to the Engine: After cooling, the oil returns to the engine to continue its lubrication cycle.

Benefits of an Oil Engine Cooler

The installation of an oil engine cooler provides numerous benefits that enhance the performance and reliability of diesel engines:

1. Enhanced Engine Longevity

By keeping the oil temperature in check, an oil engine cooler significantly reduces the likelihood of oil breakdown. Oil that is too hot can lose its lubricating properties, leading to increased friction and wear on engine components. Cooler oil helps prevent these issues, contributing to a longer engine life.

2. Improved Engine Efficiency

When oil maintains its ideal viscosity due to proper cooling, it ensures that all moving parts of the engine operate smoothly. This enhances overall engine efficiency, improving fuel economy and power output.

3. Prevention of Engine Knocking

Excessive heat can cause engine knocking, a condition where fuel ignites prematurely in the cylinder. By ensuring that the oil remains cool, an oil engine cooler helps maintain stable engine temperatures, mitigating the risk of knocking and ensuring a smoother performance.

4. Reduced Emissions

Engines that operate efficiently and are well-lubricated produce fewer emissions. By preventing overheating and ensuring that the engine functions optimally, oil coolers play a role in reducing the environmental impact of diesel engines.

5. Lower Maintenance Costs

With enhanced reliability and performance, diesel engines equipped with oil coolers often require less maintenance, saving owners both time and money in the long run.

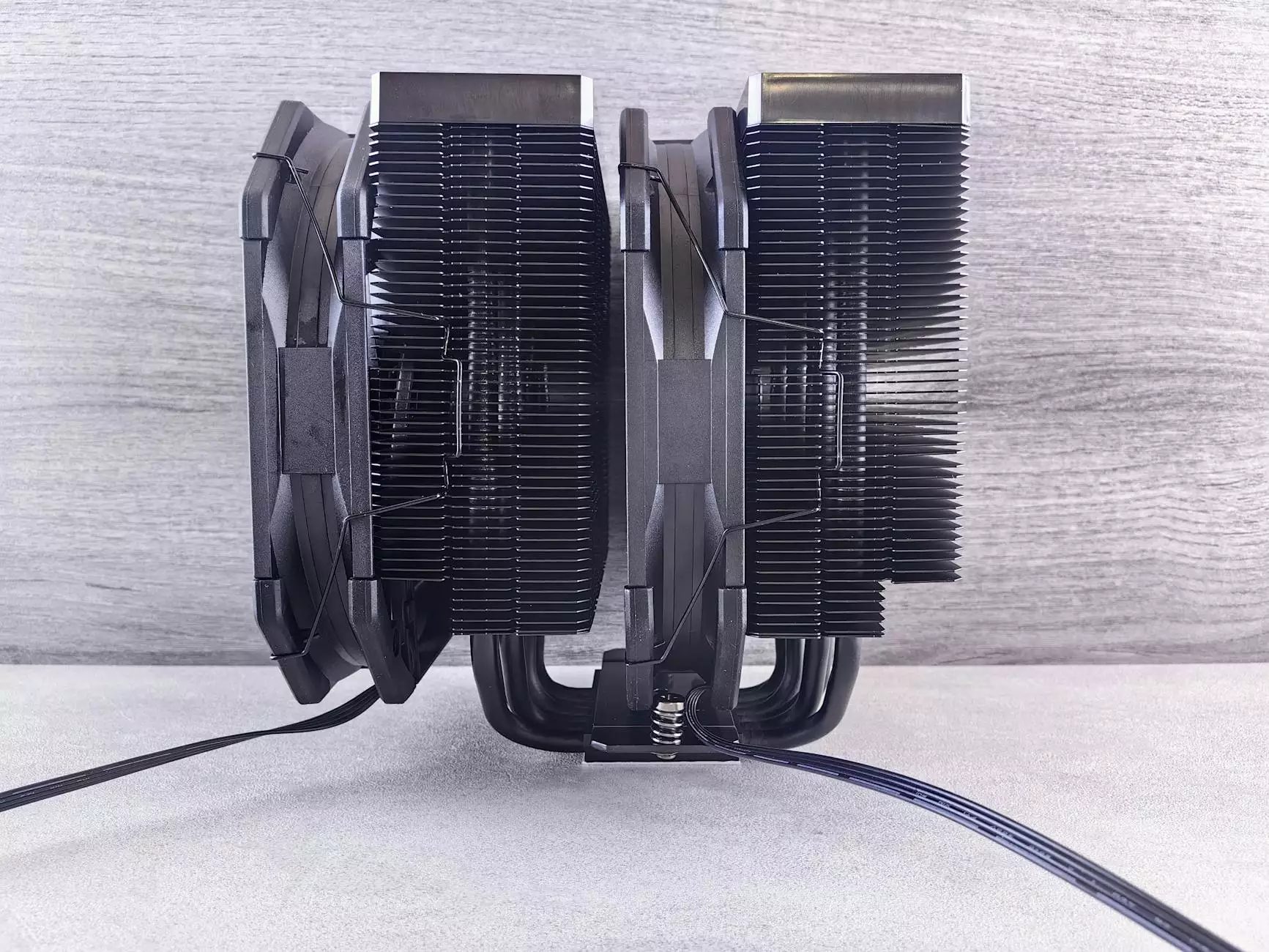

Types of Oil Engine Coolers

Oil engine coolers come in various designs, each suited for different engine setups and operational conditions:

- Air-Cooled Oil Coolers: These utilize ambient air to cool the oil. They are simple in design and commonly found in smaller diesel engines.

- Water-Cooled Oil Coolers: More efficient than air coolers, these coolers use engine coolant or water to dissipate heat from the oil. They are often used in larger and more powerful diesel engines.

- Remote Oil Coolers: Positioned away from the engine, these versatile coolers can be adapted to various installations and configurations, providing excellent cooling performance.

Maintenance Tips for Oil Engine Coolers

To ensure that an oil engine cooler operates effectively, regular maintenance is crucial. Here are some tips to keep your cooler in top condition:

1. Regular Inspections

Inspect your oil cooler and its lines for signs of wear, damage, or leaks. Address any issues promptly to prevent more significant problems.

2. Change the Oil Regularly

Following a routine oil change schedule helps prevent sludge buildup, which can affect the oil cooler’s performance. Clean oil ensures optimal lubrication and cooling.

3. Monitor Engine Temperature

Keep an eye on your engine’s temperature gauge. If the engine frequently runs hot, it could indicate a problem with your oil cooler or other cooling system components.

4. Clean the Oil Cooler

Over time, debris and contaminants can clog the cooler. Regularly cleaning the cooler, especially if it's an air-cooled model, ensures efficient heat dissipation.

Conclusion

In conclusion, the oil engine cooler is an indispensable component in the management of diesel engine performance. By maintaining optimal oil temperatures, it fosters enhanced engine efficiency, longevity, and overall reliability. Where performance matters, understanding and investing in quality engine components, like oil engine coolers, can make a considerable difference.

As a leader in the supply of diesel engine parts, client-diesel.com offers a wide range of spare parts for various diesel engines. Investing in high-quality components, including oil coolers, is essential for maintaining your engine’s performance. Explore our extensive catalog to find the perfect solutions for your diesel engine needs.